| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : EcooGraphix

Model Number : ECOO-TSR

Certification : ISO9000, CE

Place of Origin : China

MOQ : 1000 Square Meters

Price : Negotiable

Payment Terms : L/C, T/T, Western Union

Supply Ability : 2,000,000 Sqm Per Year

Delivery Time : 30 Days

Packaging Details : Standard Export Packing

Plate Type : CTP Plate

Exposure Energy : 120 - 150 Mj/ Square Centimeter

Resolution : 1-99% @ 400LPI

Spectral Sensitivity : 780 - 850 nm

Length of Run (Unbaked) : 400, 000 Impressions

Length of Run (UV Ink) : 100, 000 Impressions

Processing Speed : 0.80 - 1.20 M/Min

Application : Commercial, Newspaper and Packaging Print

Classification : CTP Printing Plates

Product name : UV Ink Capable Positive Thermal CTP Plate Double Layer 400, 000 Impressions

Storage and handling : Stored in a cool and dry environment, away from excessive cold, heat and humidity.

Shelf Life : 2 months under recommended storage conditions

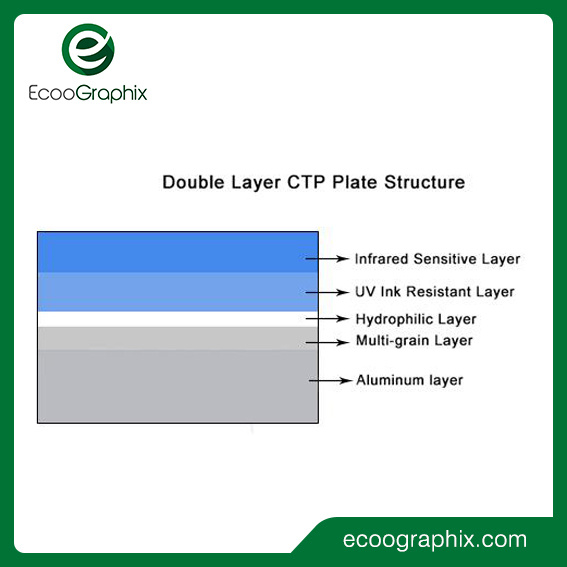

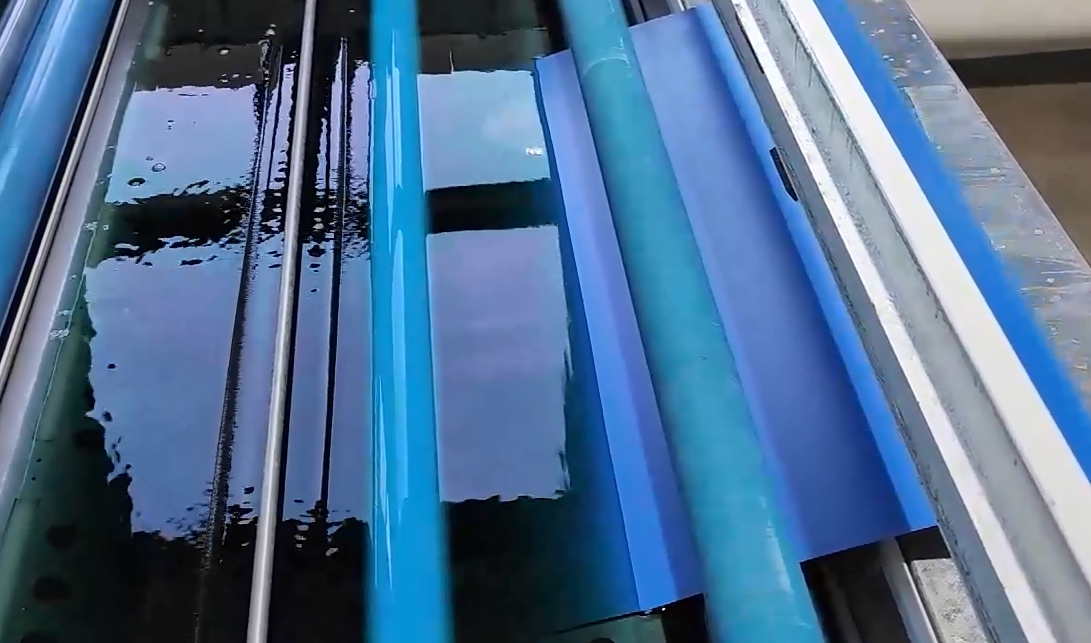

UV Ink Capable Positive Thermal CTP Plate Double Layer

400, 000 Impressions

ADVANTAGES

SPECIFICATION

Model

ECOO-TSR

Plate Type

Positive Thermal Digital Plate

Application

Commercial, newspaper, and packaging print

Substrate

Electrochemically-grained and Anodized lithographic aluminum

Gauge

0.15, 0.20, 0.24, 0.30, 0.40(mm)

Maximum short grain width

Maximum width 1280 mm

Coating

Blue

Length of Run

Unbaked: 400,000 impressions

UV Ink: 100,000 impressions

Plate setters

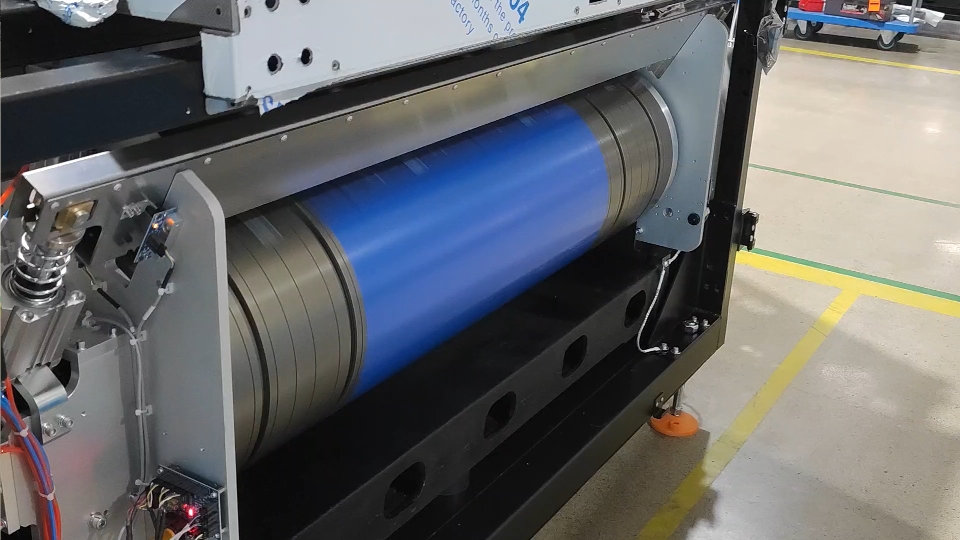

All thermal CTP machine

Aluminum

Standard 1050 Alloy

Exposure energy

120 - 150 mj/cm²

Developing time

25 - 30 sec

Spectral Sensitivity

780 - 850 nm

Resolution

1-99% @ 400LPI

Developer

ECOO DV-T Series Developer

Processing temperature

23ºC +/- 2ºC

Processing Speed

0.80 - 1.20 m/min

Safelight

Daylight handling

Shelf life

12 months under recommended storage conditions

Packaging

Available in all standard formats, including bulk packaging options such as APL packaging

Storage and handling

Stored in a cool and dry environment, away from excessive cold, heat and humidity

| Model | ECOO-TSR |

| Plate Type | Positive Thermal Digital Plate |

| Application | Commercial, newspaper, and packaging print |

| Substrate | Electrochemically-grained and Anodized lithographic aluminum |

| Gauge | 0.15, 0.20, 0.24, 0.30, 0.40(mm) |

| Maximum short grain width | Maximum width 1280 mm |

| Coating | Blue |

| Length of Run | Unbaked: 400,000 impressions UV Ink: 100,000 impressions |

| Plate setters | All thermal CTP machine |

| Aluminum | Standard 1050 Alloy |

| Exposure energy | 120 - 150 mj/cm² |

| Developing time | 25 - 30 sec |

| Spectral Sensitivity | 780 - 850 nm |

| Resolution | 1-99% @400LPI |

| Developer | ECOO DV-T Series Developer |

| Processing temperature | 23ºC +/- 2ºC |

| Processing Speed | 0.80 - 1.20 m/min |

| Safelight | Daylight handling |

| Shelf life | 12 months under recommended storage conditions |

| Packaging | Available in all standard formats, including bulk packaging options such as APL packaging |

| Storage and handling | Stored in a cool and dry environment, away from excessive cold, heat and humidity |

FEATURES

- Positive writing thermal plate

- Double layers system

- Made with a high-grade aluminum base

- Wide adaptability for different plate setter brands

- Non-ablative coating

- Run lengths up to 150,000 impressions

- UV ink up to 80,000 impressions

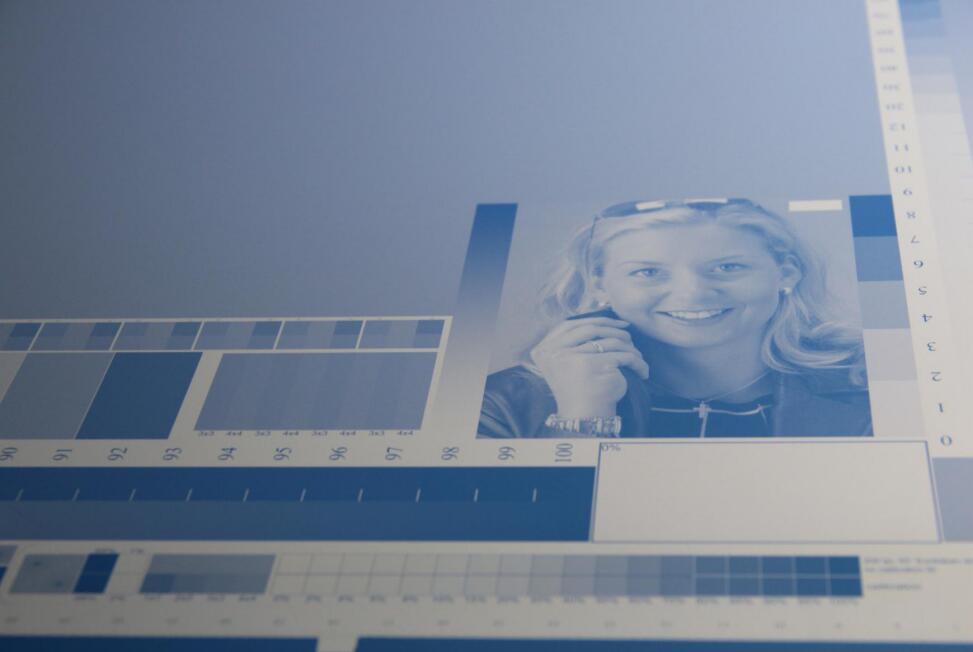

- Ability to print both AM and FM screening

BENEFITS

- Extensive adaptability, saving from waste during possible swift of consumables' supplying

- Quick turnaround time on press

- Compatible with common developers

- Premium quality of dot reproduction and super long run length

DETAILS

PRODUCING AND PACKAGING

From production to delivery, we make every detail very carefully to guarantee good product quality and service to customers.

CERTIFICATES

FAQ

1. Q: How long is the lead time?

A: The lead time is normally 45 days.

2. Q: Do you offer free plate samples?

A: Yes, we offer free testing samples maximum 12 pcs for each size but with delivery fee to collect.

3. Q: How do you guarantee stable quality?

A: There are 3 inpecting procedures: 1, automatic on-line 24h scanning detector; 2, random sampling per 15 mins at the producing line; 3, manually full inspection before packing. The production is mature. It is not a new product to us.

4. Q: Do you have accompanying plate making products to enable one-stand easy purchase for some end users?

A: Yes. CTP machine, processors, violet plate, CTP-CTCP plate, chemistry(fountain solution, roller wash, etc.) are all available to make your purchase more easily.

5. Q: Payment term?

A: Normally, 30% deposit, 70% before shipping, or LC at sight.

6. Q: Is refrigerating container necessary for shipment?

A: No. The plate is relatively stable and mature. So normal container is enough unless some ertreme hot situations.

|

|

UV Ink Capable Positive Thermal CTP Plate Double Layer 400, 000 Impressions Images |